INDIVIDUAL MANUFACTURING PROCESSES

THAT MEET THE HIGHEST DEMANDS AND DELIVER MAXIMUM PRECISION

CUSTOMISED HIGH PRECISION TOOLS OUR STANDARD IS UNIQUE

Whether conventional or automatic – MPK’s select machine park caters for shrink and joining technology as well as flat grinding, external and internal grinding of contours and profiles, starting hole shooting, wire and sink erosion, carbide milling and finishing – all offered in the highest precision. The broad-based range of vastly different manufacturing processes spans a large number of complex customer components. The perfect interplay of experience and innovation as well as our technological breadth means that we are capable of meeting highest quality demands and short delivery deadlines.

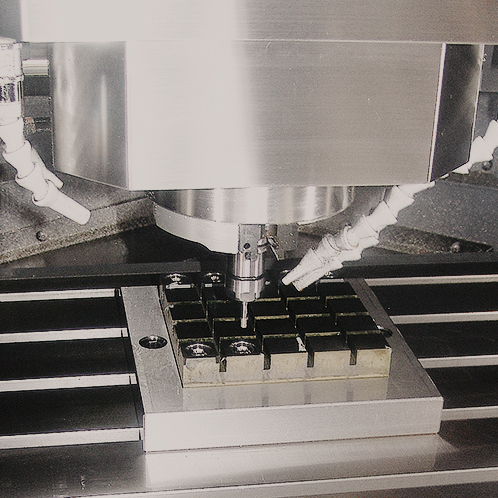

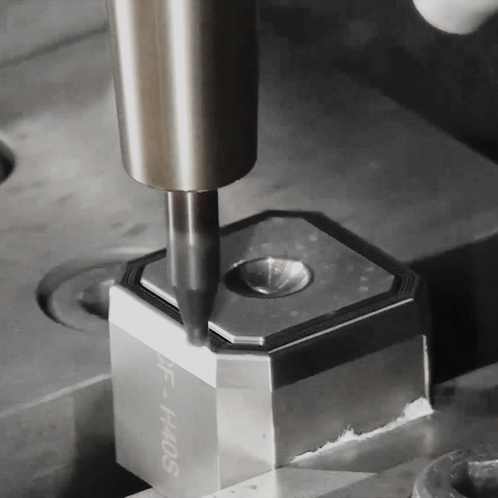

EROSION

Spark erosion comes into play when the mechanical working of difficult-to-machine materials begins to hit its limits. The process enables the manufacture of complex shapes and cones with extremely detailed surfaces in all conductive materials – and this includes hardened steel, titanium, or carbides. Our comprehensive technical knowledge is based on decades of experience in erosion technology spanning a vast range of branches and our 18 machines cater for the two main methods of wire and sink erosion

Both methods can be used for wage erosion as well as complete manufacture. It is precisely in the manufacture of sharp-edged pockets and holes that this modern technology comes into its own.

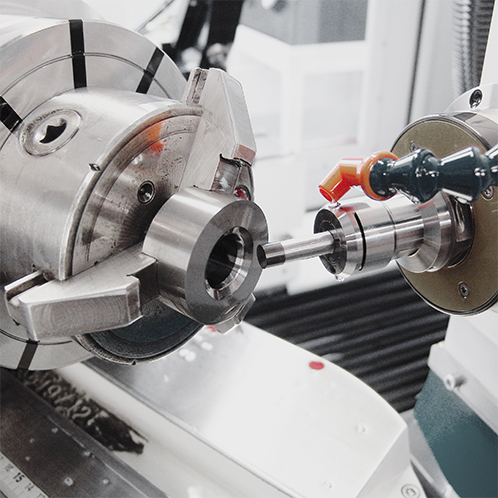

MILLING

One of our manufacturing processes that finds daily application is the CNC milling of carbides, steel, and tungsten copper. Our modern machine park equipped with Yasda- and Makino milling technology offers various machining possibilities, enabling us to process the tiniest of component at a corner radius of up to 0.03mm. During this, dimensional precision, depending on the contour in question, can reach < 5µm. Outsourcing the milling process to MPK Special Tools means efficient contract processing and reduces your costs, allowing you to profit from our specialist experience in precision machining.

We can accurately mill with a high degree of precision both on a customised and flexible basis, providing tool solutions according to customer demands from the most suitable raw material. Our carbide milling service helps you to increase your productivity, competitiveness, and flexibility. Our tested surface qualities ensure longer service lives and 100% reproducibility of geometries.

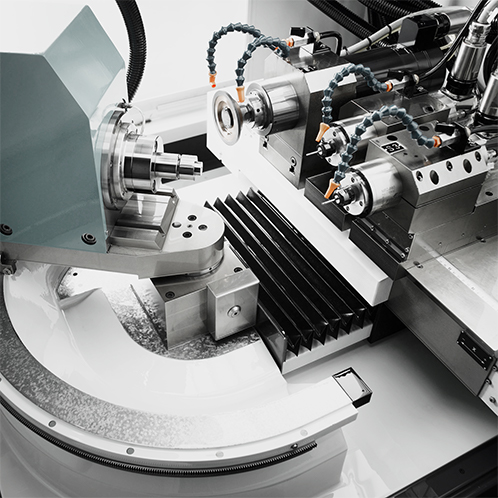

GRINDING

High demands made on achievable tool surfaces calls for grinding technology. The process of surface processing with very precise accuracy attests to the good machinability of hard materials in particular. The grinding technology is frequently employed if low ridging and coarseness of the surface as well as high dimensional accuracy is needed.

For the μ-precision machining of external and internal surfaces we ensure the highest precision in accordance with your requirements.

MPK Special Tools GmbH ALWAYS AT YOUR SIDE

Technical support and customised solutions:

We can employ our extensive experience and know-how to support you with customised tool solutions. For even more specialised and tricky tasks we can manufacture special solutions that are exactly tailored to the respective application and can also be reproduced many years later.

QUERIES AND SUPPORT

Do you require help or have a query? Then get in touch with us:

Tel. +49 7171 92524-0

info@mpk-specialtools.de